HIGH PRESSURE SHOWERS PROJECT – SUSTANA/ROLLAND PLANT IN ST-JEROME QUÉBEC.

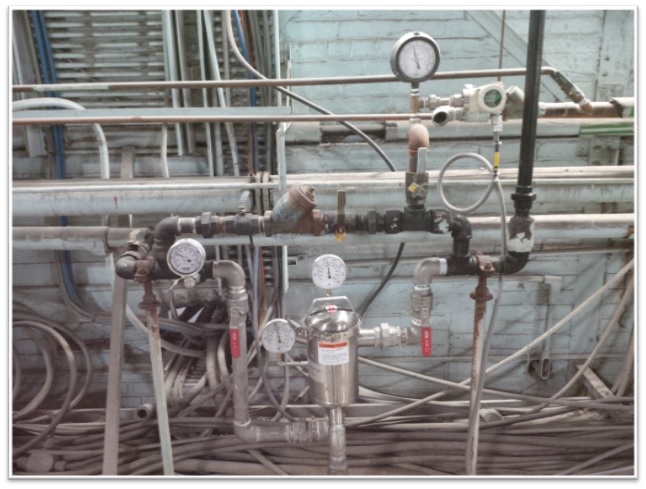

Application

The high-pressure shower project aims to put high-pressure showers into operation to allow optimal conditioning of covering elements on the paper machine.

Solution

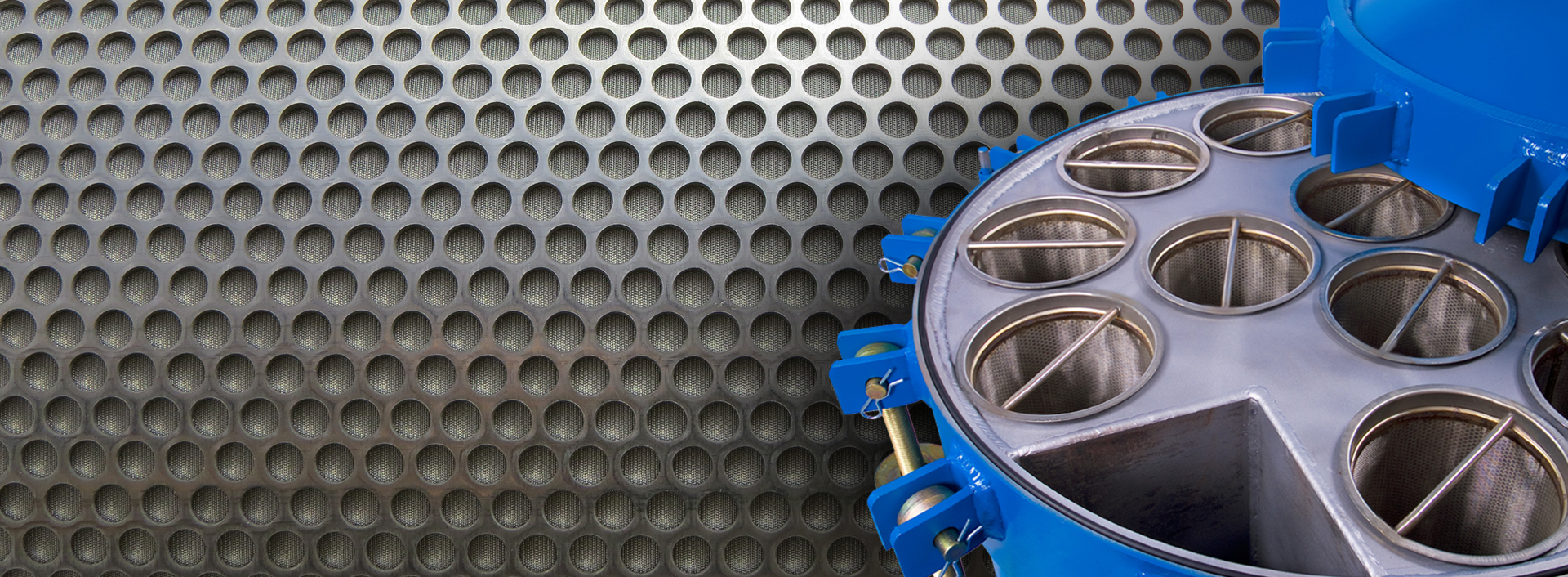

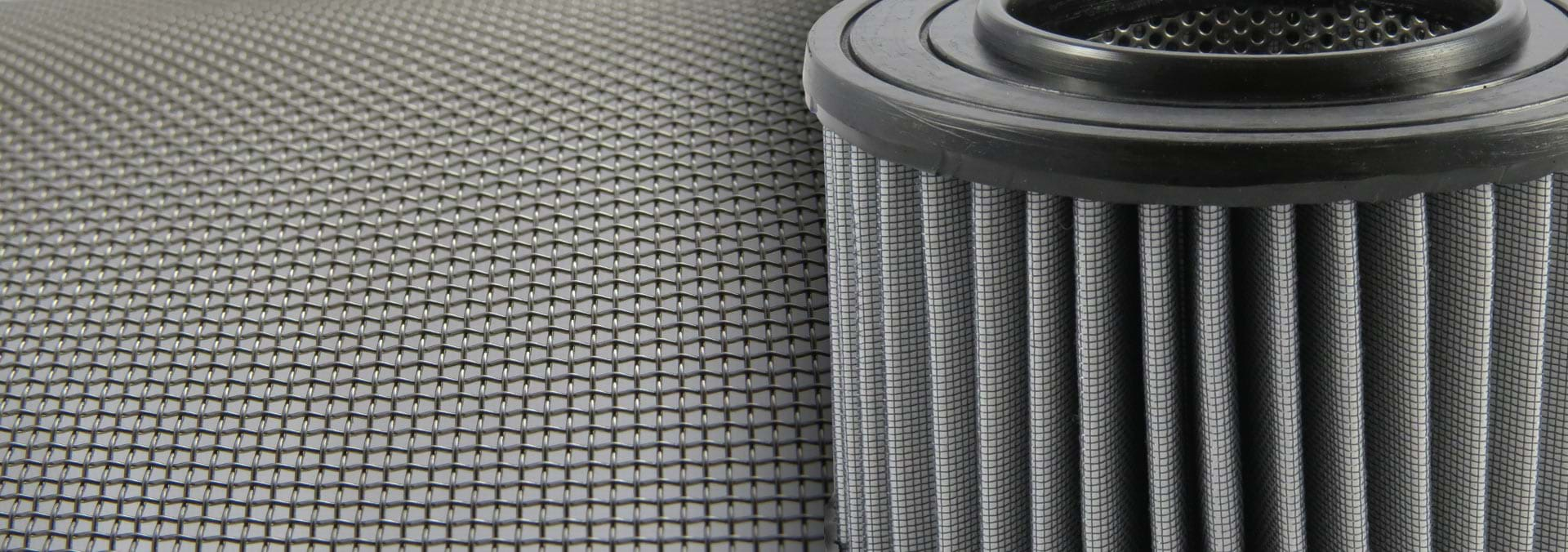

Sizing of new DUPLEX filters allowing 100 micron filtration of the water in the 3 new showers on the wet end of the paper machine

GAIN OBTAINED: No more shower nozzles plugging since the installation was made.