-

A solution-centered environment…

A solution-centered environment…Our goal is to find solutions for enhanced systems, reduce the frequency of filter replacements, and improve the optimal performance of the processes involved.

-

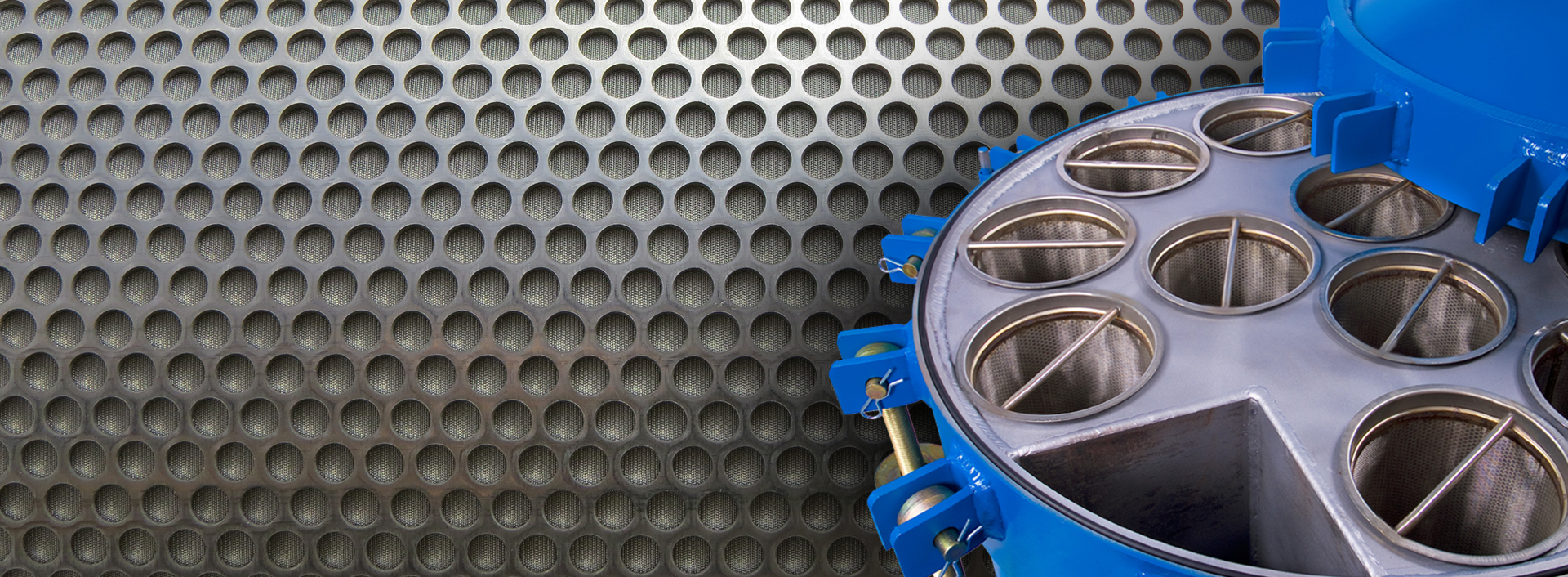

Filtration is an art form to us…

Filtration is an art form to us…Filtration is an untapped sector where each project comes with its own set of specifications, which is why Filtrindustries has developed a customized approach that allows providing clients with solutions tailored to their exact needs.

-

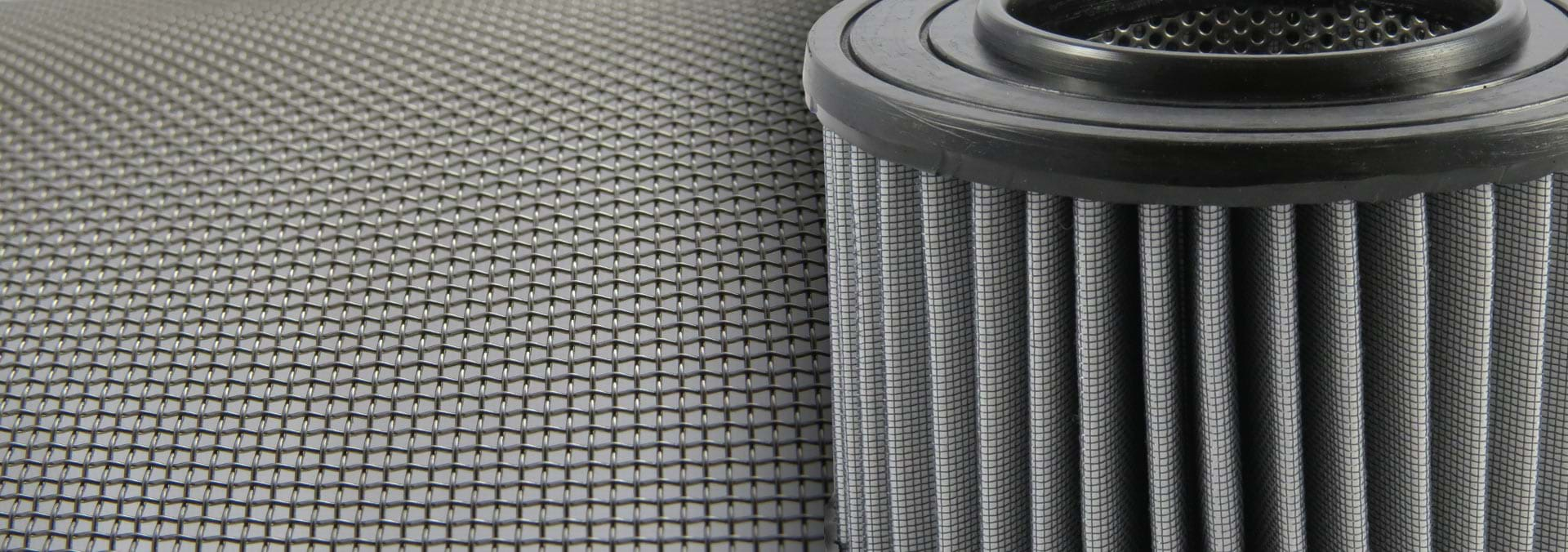

Opt for hydrocarbon filtration

Opt for hydrocarbon filtrationFiltrindustries proposes comprehensive contamination control solutions through the use of oil purification systems, breathers, and replacement components that will extend the service life of equipment and non-renewable fluids.

-

Specialized in customized filters

Specialized in customized filtersFiltrindustries has developed its very own trade mark in order to offer high-end products tailored to your specific needs. Furthermore, the company can help you locate rare or imported filters.

-

Expertise in all industry types

Expertise in all industry typesFiltrindustries provides consulting services for the development, installation, or maintenance of comprehensive filtration systems. Be it water, air, gas, or oil filters; entrust us with your project!

-

Sustainable Development Solutions

Sustainable Development SolutionsFiltrindustries seeks to develop sustainable solutions for the environment by reducing the number of filters replaced, by using self-cleaning filters instead, and by promoting water recycling in as many processes as possible.